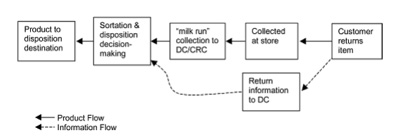

Reverse logistics stands for all reuse of products and materials associated activities. It is the method of planning, implementing and managing the efficient, cost-effective flow of raw materials, in-process inventory, finished products and associated data from the point of consumption to the point of origin for the purpose of recovering value or correct disposal. More precisely, reverse logistics is the process of moving goods from their typical final destination for the purpose of capturing value, or proper disposal. Remanufacturing and rehabilitation operations may also be included in the reverse logistics definition.” The method of reverse logistics involves the management and sale of surplus as well as returned materials and machines from the leasing of hardware. Logistics normally handle incidents that introduce the item to the client. The resource comes at least one step back in the supply chain in the event of reverse logistics.

If the product of a manufacturer usually passes through the network of the supply chain, it is to reach the distributor or client. After selling the item, any method or management includes inverse logistics. If the product is defective, the customer would return the product. The manufacturing firm would then have to organise shipping of the defective product, testing the product, dismantling, repairing, recycling or disposing the product. The product would travel in reverse through the supply chain network in order to retain any use from the defective product. The logistics for such matters is reverse logistics.

The traditional logistics flow is described by the Supply Chain Management Professionals glossary as: “Process of planning, implementing and managing efficient, cost-effective raw material flow, in-process inventory, finished products and associated data from the point of origin to the point of consumption in order to comply with client demands”.

The same glossary defines reverse logistics as: “The process of planning, implementing and controlling efficient, cost-effective raw material flow, in-process inventory, finished goods and related information from the point of consumption to the point of origin for the purpose of recovering value or proper disposal.”